Packing Solution for Boxes & Trays

Fully Automated

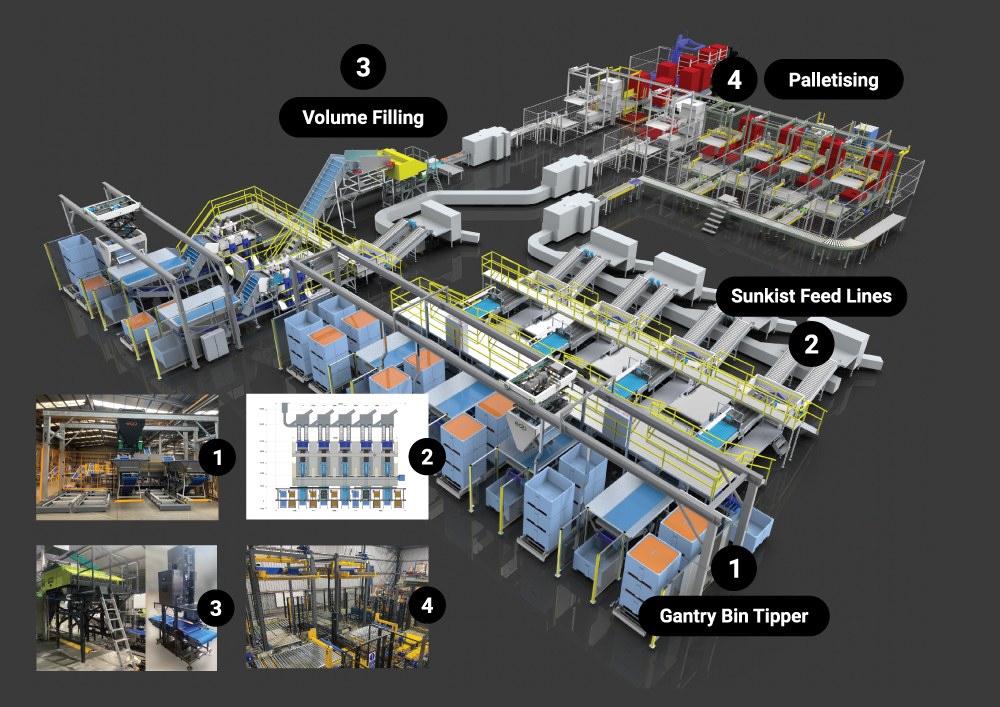

The Fully-Automated Packing Solution for Boxes and Trays is a modular machine line designed to reduce manual labour in end-of-line packing. It automates the handling and placement of products into both boxes and trays, improving efficiency and consistency while lowering reliance on manual operators. Built for flexibility and integration, it supports a range of product types and packing formats with minimal changeover time.

Key Features:

Gantry Bin Tipper

Efficiently handles fruit, vegetables, and more—this bin tipping system suits 1165mm plastic bins (up to 600kg) with speeds up to 63 bins/hour. Featuring up to 8m gantry width, integrated conveyors, multi-hopper feed, and safety elements like light curtains and soft tipping.

Sunkist Feedlines

Single or Multiple Pattern Packer Feed Lines. Customisable setups include bin tippers for fruit unloading, creep feed hopper, roller elevator with inspection table, singulator for sticker machines, 1-tonne accumulator for product storage, and roller elevators to feed the Pattern Packer.

Volume Filling

High-Performance Packing Line

Includes edp Bin Tippers matched to line speed, a 3-way creep feed hopper, 1200mm or 1500mm roller inspection table, waste and seconds conveyors, up to 8-lane singulators, and elevator to either a high-capacity Combination Weigher or Pre Pack XL model…

Palletisers

The system has a capacity of up to 15 boxes per minute or 2.5 layers per minute. Optional features include a box stacker to increase throughput to 20 boxes per minute, a layer centering mechanism, and a soft box turner. It can also be programmed to position box labels facing outward on the pallet.

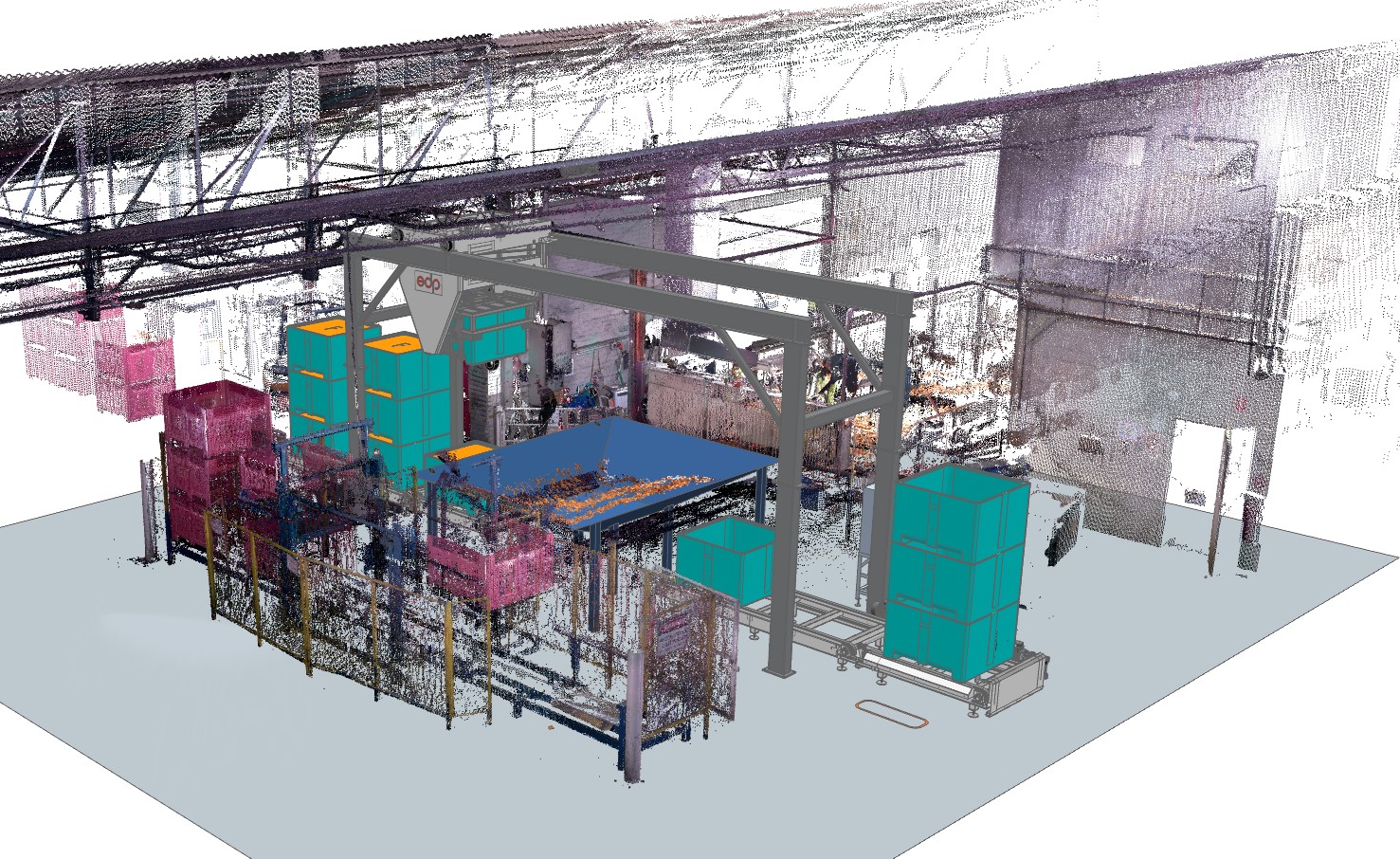

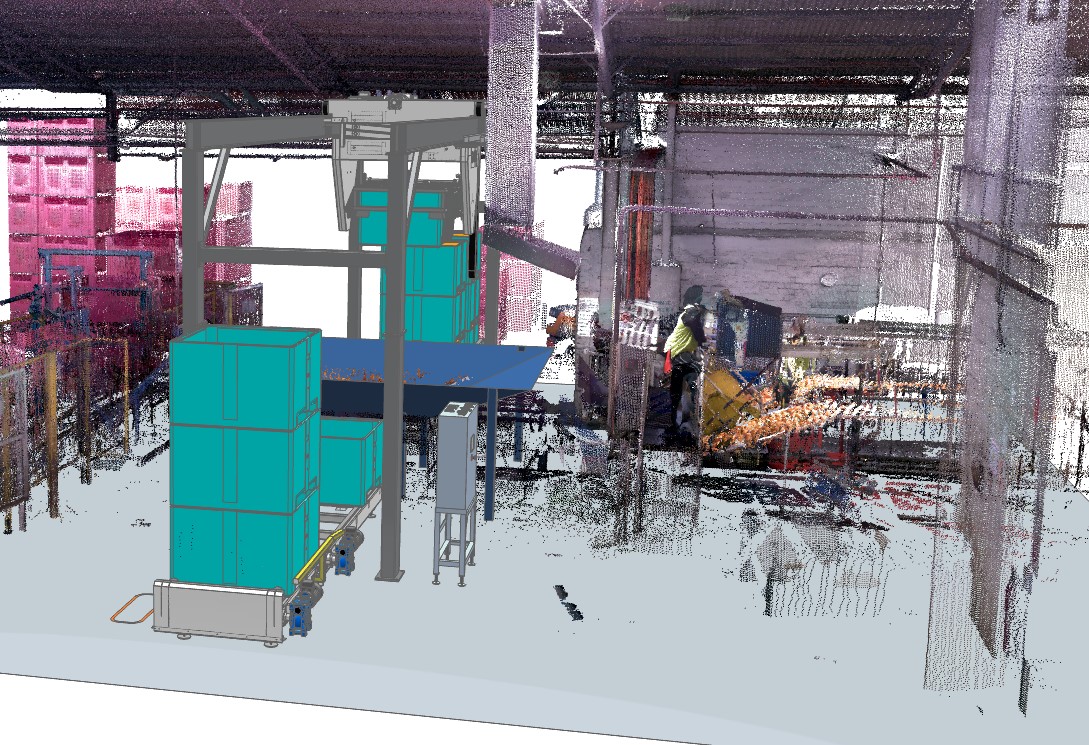

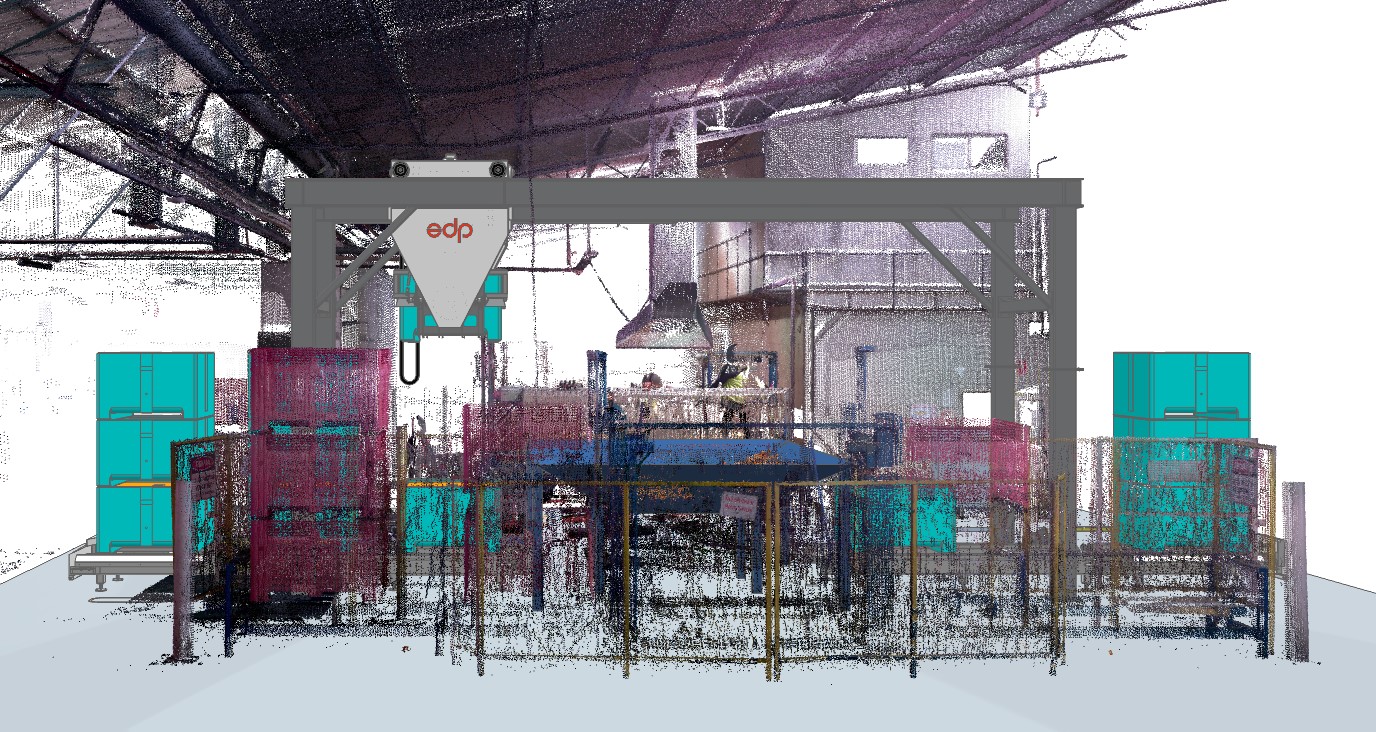

Complete 3D Shed Scanning Available

edp offers advanced 3D shed scanning to ensure your new machinery fits perfectly. Our scanning technology captures precise measurements of your space, allowing us to design custom solutions that integrate seamlessly into your existing shed layout—saving time, avoiding costly errors, and ensuring smooth installation.

Reliable and Renowned

An original equipment manufacturer, edp has a well established export market as well as strong associations with European manufacturers to offer the best technology in the world of fresh produce packaging and handling equipment.

edp

edp is a leading Australian supplier of fresh fruit and vegetable grading & packaging solutions including machinery and consumables.

Contact Us

33 – 37 O’Brien Street,

PO Box 251

Mooroopna VIC 3629

Australia

Useful Links

Newsletter

Please enter your email to keep up-to-date industry updates, news and support.